Remote Site Management

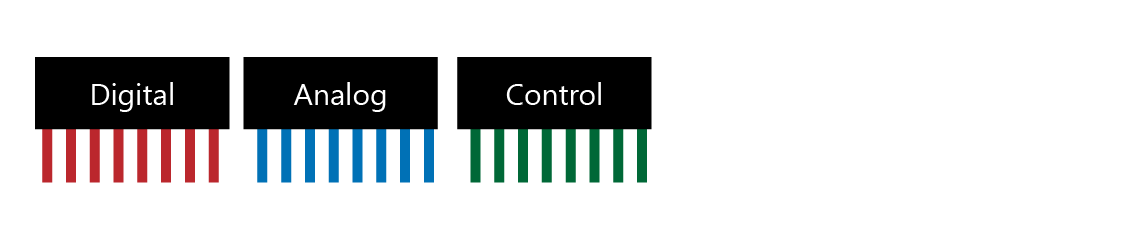

I/O

Plateau offers an efficient, 24 total channels of interface. This is split into 8 Control outputs, 8 Digital Inputs, and 8 Analog Inputs (0-25v / 4-20mA). Optionally all I/O on Plateau can be electrically isolated for use in sensitive, negative, or ground isolated systems. All I/O on Plateau is presented on platinum plated, individually isolated, locking keyed connectors.

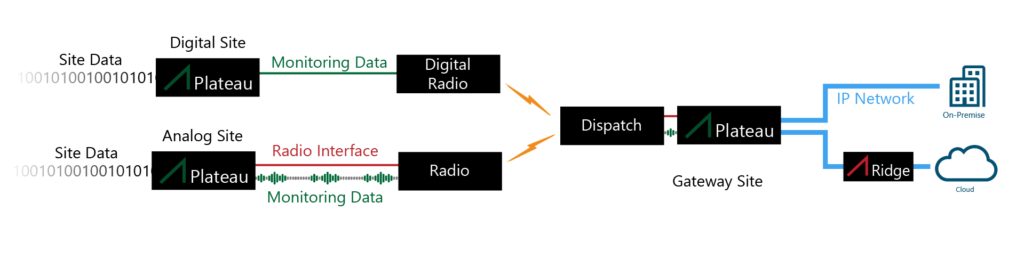

No IP, No Problem

Plateau is specifically engineered for locations with limited backhaul options. Options include, RS232 Serial, FFSK, 4-Wire E&N Signalling.

Engineered for the Back Country

Because the optimal location for critical equipment is often not the optimal location for support services, power, backhaul, etc. Summit has been engineered to consume the absolute minimal amount of resources while delivering its full complement of features. Consuming at maximum only 16 mA Summit is on average 4-5 times more efficient when compared to the competition.

Data Logging

When it is not critical to know all events exactly the moment they occur, Plateau can be put into store and forward mode. This mode allows for data to be captured during a predefined period and relayed back to Apex at a convenient time, 3:00 am for example.

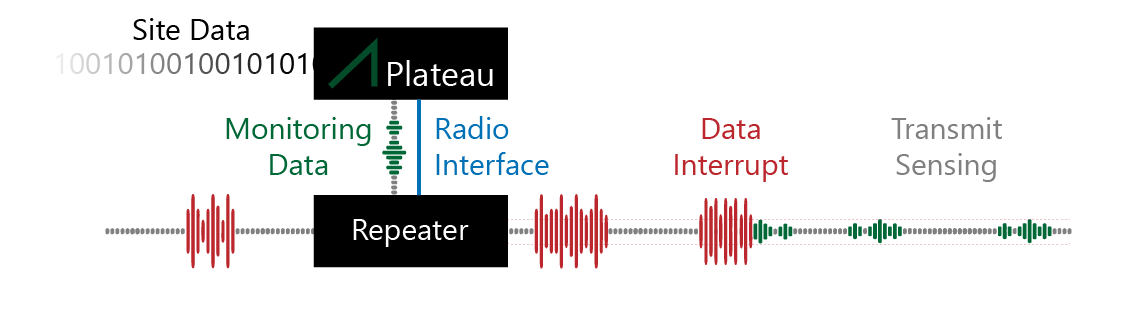

Single channel backhaul

In environments where redundant backhaul is not an option Plateau can operate in single channel mode. In this state Plateau is able to monitor the channel for activity and only transmit information when it is clear to do so. Further depending on the installed radios these transmissions can be injected and received without breaking squelch, and reminding everyone just how much they missed answering a call from a fax machine.

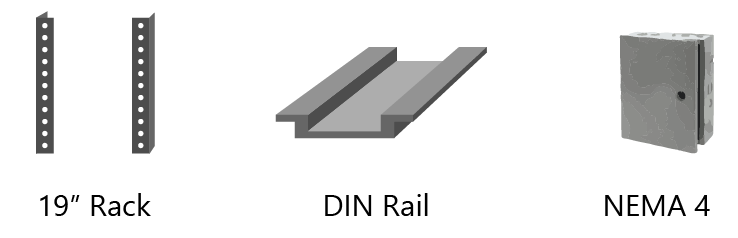

Enclosure Options

Plateau is deployable in a range of physical formats. The standard 19” rack configuration occupies just 1U of rack space. Standard DIN rail mounting hardware is available for applications where rack-mount equipment is not used. In outdoor or uncontrolled environments a NEMA4 rated enclosure is available to ensure reliable function even in the most harsh conditions.

Industrial Internet of Things

The Industrial Internet of Things (IIoT), also known as the Industrial Internet, brings together brilliant machines, advanced analytics, and people at work. It’s the network of a multitude of devices connected by communications technologies that result in systems that can monitor, collect, exchange, analyze, and deliver valuable new insights like never before. These insights can then help drive smarter, faster business decisions for industrial companies.

Applications

-

DAS monitoring

We provide monitoring and control solutions for Distributed Antenna System (DAS) technologies.

-

SCADA Applications

Our solutions give visibility to the health of your new or existing SCADA infrastructure.

-

Critical Communications

For systems that require guaranteed up-time, including public safety and emergency services.

-

Public Safety Networks

For systems that require guaranteed up-time, including public safety and emergency services.